Local Fermentation FeatureUpdated 2 years ago

Congratulations on your choice of the 360 series controller. With the advent of revisions starting November 1, 2019; most if not all main brew control panels (excludes Nano Electric) will have capacity for up to 2 Local Fermentationvessels to be controlled by the same brewing control panel that you use to brew. This means we have added the capacity to control the heater and cooling solution for 2 fermentation vessels. We based our design on the Spike Brewing CF series conical fermenters but paired with 120v fountain pumps*.

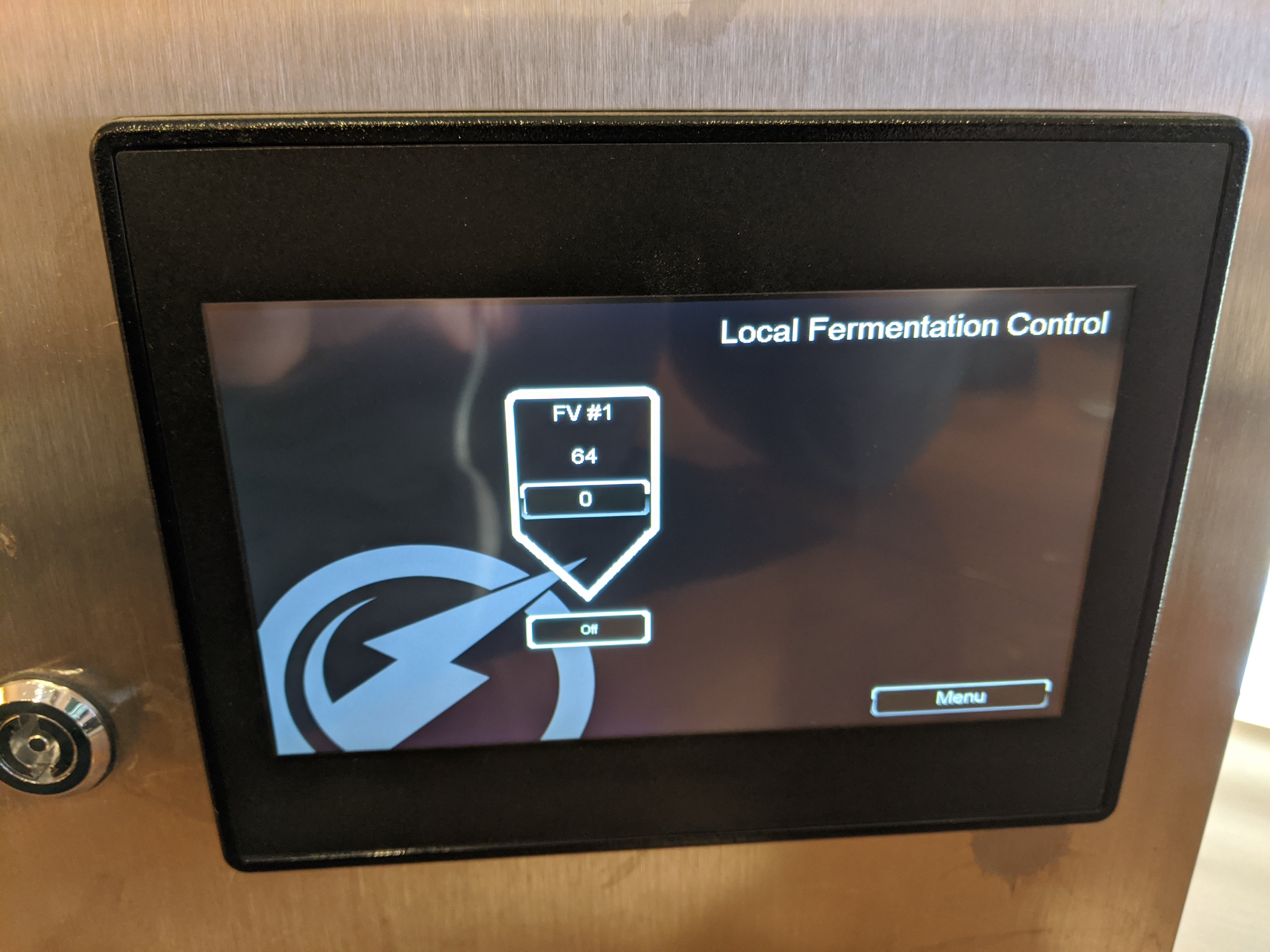

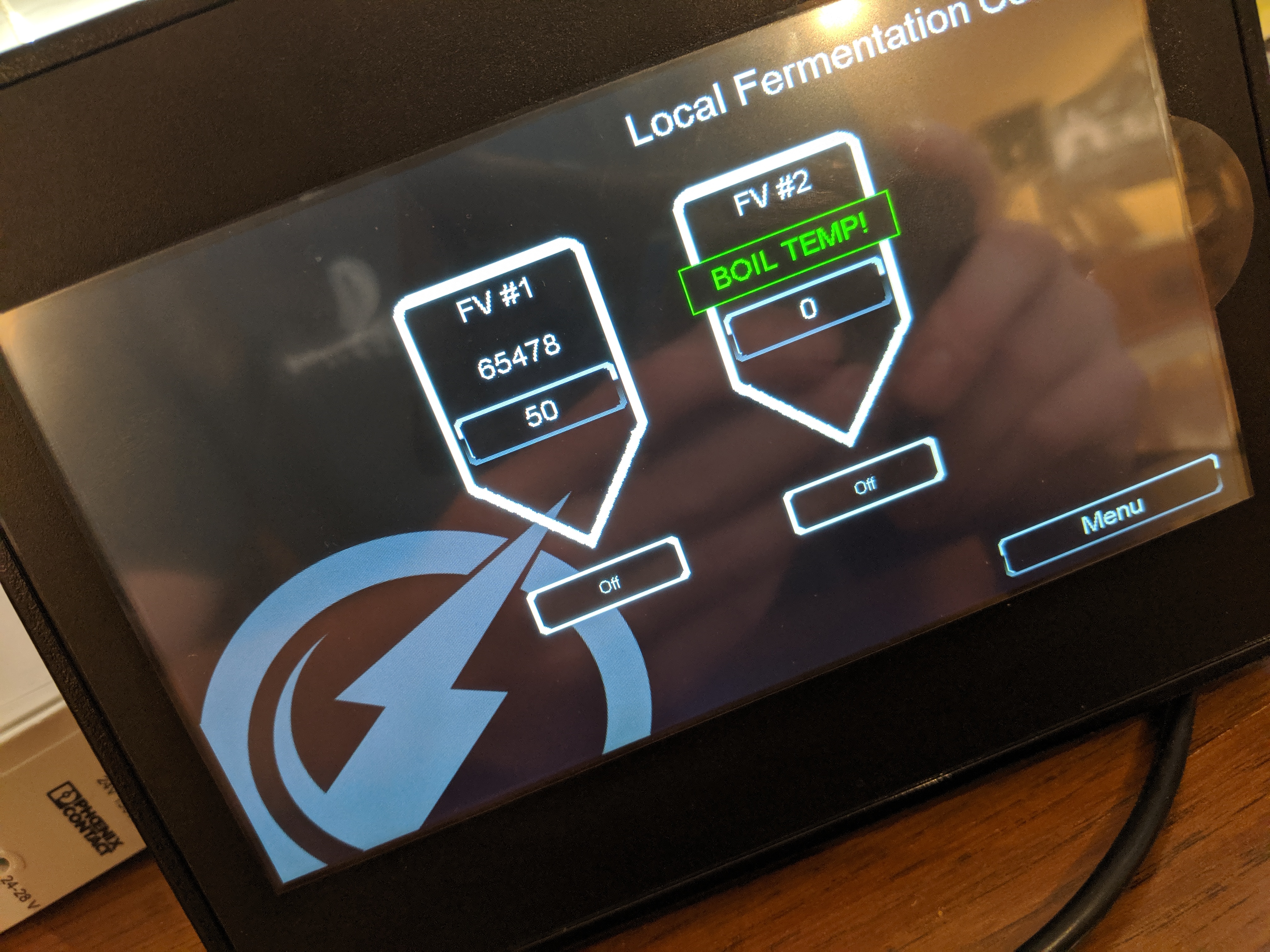

As you see in the picture, we have the first one enabled. Via setup the second can also be enabled. By default we ship with FV #1 enabled, and FV #2 disabled so that boil temp can remain as such.

In order to use FV #2, we hijack the boil temp point but we make it possible to swap between the two by way of the home page. Since boil is typically controlled in manual mode, this is feasible, but by way of temp you can still maintain temp holds for step boils or kettle souring.

You'll find the ports on the bottom side of the panel, in order of use from back to front, pumps, FV #1 and FV #2. For the FVs, the plugs are then placed heat output and cool output side by side.

You will need appropriate Neutrik connectors, or our PowerCon jumpers, available on the site.

*Depending on the vessel size, there are many options for a 120v fountain pump from vendors like Amazon. We found over the years that the DC pumps that ship with power suppliers have a tendency to cause hanging power issues. As we are running 24v and most brewer pumps are 12v, the cost impact is notable enough that sticking with 120v is the best solution. Your amp draw will be nominal.